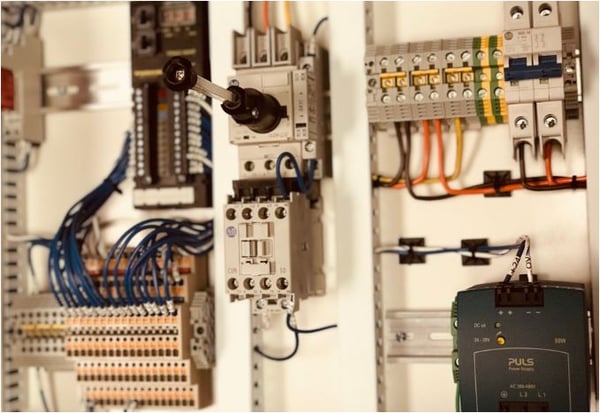

Conveyor Handling Company's (CHC) in-house control systems, for small and large systems, is based on a multi-protocol industrial Ethernet remote I/O system, providing scalability and modularity required by material handling systems. The system places remote I/O modules and motor control devices directly on the equipment, near the point of use, linking them together with a multi-protocol industrial Ethernet network system.

Conveyor Handling Company's (CHC) in-house control systems, for small and large systems, is based on a multi-protocol industrial Ethernet remote I/O system, providing scalability and modularity required by material handling systems. The system places remote I/O modules and motor control devices directly on the equipment, near the point of use, linking them together with a multi-protocol industrial Ethernet network system.

Field devices, to include motors and photocells can be monitored and controlled locally by a central Programmable Logic Controller (PLC) via the network. This eliminates the need for a large, custom designed central PLC panel and the need to run large bundles of control and motor power wires from the central panel out to each field device. This speeds up the installation process, reducing the pre-installation engineering. As the length of the electrical installation decreases, the system can be turned over faster. Furthermore, as the installation is accruing, parts of the system can be brought online, further decreasing the overall system startup time.

The decentralization of the control system allows the material handling system to be scalable, so that additional equipment can be integrated into a preexisting system simply by placing the equipment, supplying it with power, plugging it into the network, and configuring the software in the central PLC to recognize the new network node.

For simple 1-2 conveyor projects, CDCA (Conveyor Handling Distributed Control Architecture) can act as a stand alone controller. If the system complexity ever changes and an Ethernet based PLC can be added for supervisory controls to become the master of the CDCA systems. CHC's multi-protocol hardware allows for the adaptation to any PLC manufacturer that the customer specifies including Allen-Bradley, Siemens and Mitsubishi.

Benefits to Implementing a CHC Control Systems:

-

The central controller can be eliminated for simple conveying applications

-

Based on the application (and if desired), local control can still be maintained, even if the main PLC becomes nonfunctional or communication is lost

-

Easily and more cost effectively expand your system, in both brown and green field applications

-

Distributed I/O modules capable of operating on their own as small scale, free-standing local controllers

The advantage of free-standing local controllers is that CHC can provide the flexibility of a programmable control without the cost and complexity of a large central PLC control system. This reduced cost makes it practical to apply programmable control to small systems which previously could not justify the expense. While as still providing the flexibility to scale to a much larger system.

For more information regarding Conveyor Handling Company's control system and the benefits it may have for your company's operation, talk to your Sales Engineer.

Conveyor Handling Company (CHC) was founded in 1975 with sales and service branches along the Mid-Atlantic region. Our material handling solutions include: