|

|

|

|

|

|

|

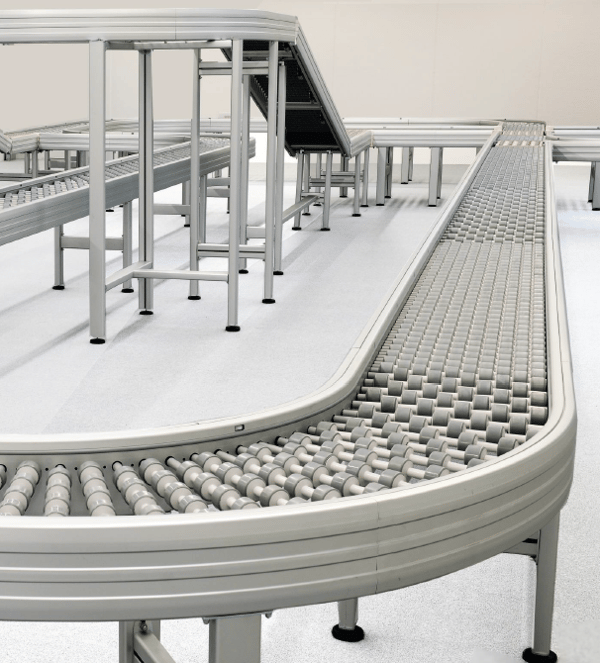

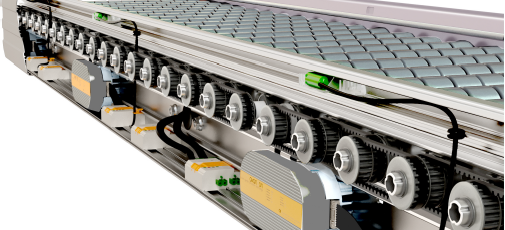

The up/down zone powered conveyor (ZPC), by Avancon, is a modern avant-garde conveyor featuring self-contained roller-conveyor and belt conveyor systems. The system works automatically and is autonomously fully functional, electronically controlled and powered in zones. Avancon calls it the "ZPC-Concept". It is able to accumulate with zero pressure and saves up to 84% energy. Additionally, it has the capability to incline up and down up to 15° with or without a belt. The up/down zone powered conveyor (ZPC), by Avancon, is a modern avant-garde conveyor featuring self-contained roller-conveyor and belt conveyor systems. The system works automatically and is autonomously fully functional, electronically controlled and powered in zones. Avancon calls it the "ZPC-Concept". It is able to accumulate with zero pressure and saves up to 84% energy. Additionally, it has the capability to incline up and down up to 15° with or without a belt.

The key to the conveyor system technology is in the fine anodized aluminum, torsion resistant frame construction. The photo-sensors are mounted in a transparent and protected housing inside the profile frame. All drive and control elements are inside the closed profile frames, allowing the system to be kept very clean and safe while still easily accessible, if needed. Additionally, Avancon's OTU (omni-directional transfer unit) can fit into any conveyor system to achieve transfers from 0-90° with fully controllable speeds for transport and divert.

ADDITIONAL FEATURES & BENEFITS

- Maximum speed up to 1.5 m/s (4.92'/s)

- Maximum load of 100 lbs.

- Straight sections, curves, mergers and diverts available

- Enormous variety of shaft configurations

- Low to zero maintenance

- Polyurethane and polyamide tires

To further inquire about Avancon's ZPC conveyor system and the benefits and advantages it may have for your company's operation, please reach out or contact your Sales Engineer.

Conveyor Handling Company (CHC) was founded in 1975 and is an industry leading material handling systems integrator. We provide complete turnkey engineered material handling integrated systems, engineering and installation services, preventative maintenance, and 24/7 repair service across the Mid-Atlantic region. Our material handling solutions include:

Conveyor Solutions, Automated Storage Solutions, Palletizing, Picking Systems, Scanning & Vision Systems,

Automated Guided Vehicles, WCS Software & Controls, Rack, Shelving & Storage Equipment

|

|

|

|

|

|

|

|

|

|

|