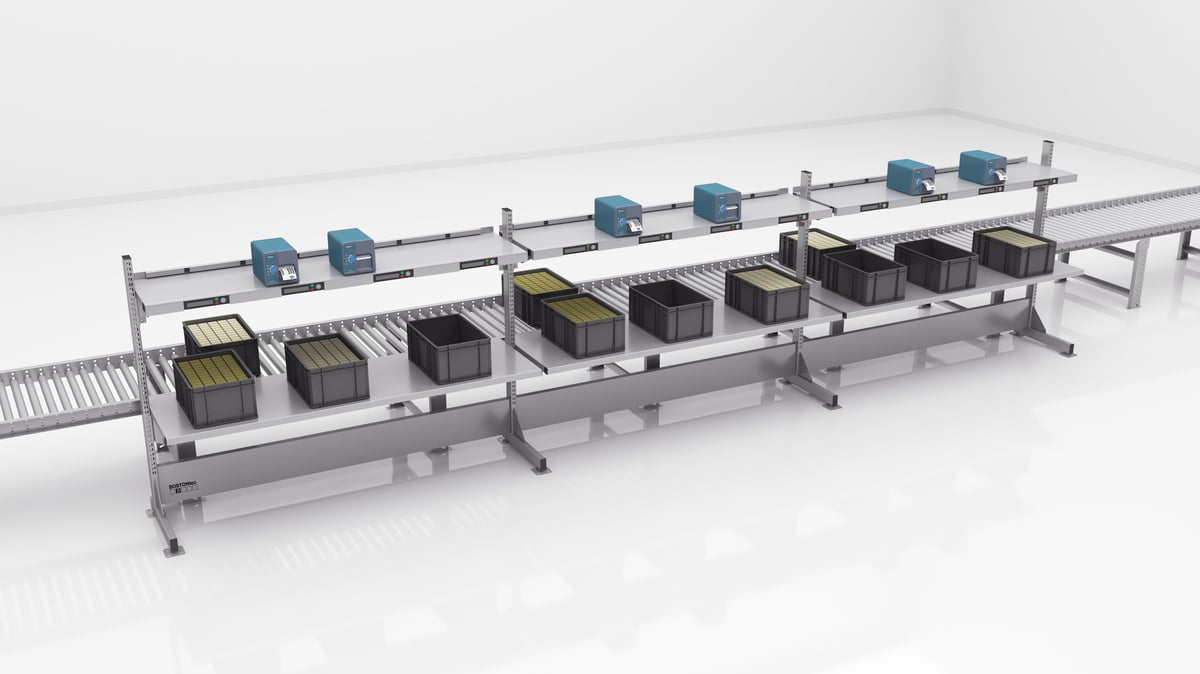

As part of an innovative batch picking solution, BOSTONtec designed custom batch stations to work in conjunction with Kardex vertical lift modules to maximize throughput of fulfillment operations. These stations are placed side by side in the access area of the automatic storage and order retrieval system. The lower shelves serve as a work surface and set at the ergonomic height to allow the operators to put retrieved items into the totes easily. The upper shelves hold the label printers.

Put-to-light devices are mounted on the upper shelves to guide the operators to put the correct number of items into the respective bin to finish up picking a batch of orders simultaneously. Totes with completed orders are pushed off the station onto the conveyor to be taken to the next work area for packaging and shipping.

BOSTONtec's batch stations are a cost-effective and space-saving setup that can be customized to integrate smoothly with various storage solutions to expedite the picking process.

ADVANTAGES INCLUDE: