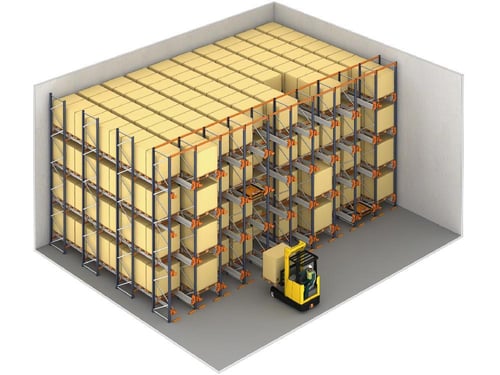

Interlake Mecalux's Pallet Shuttle is a high-density storage system to save space, time and increased productivity. Adapted rack structures allow for an electric run shuttle to move inside storage lanes along a track, following commands using a WiFi control tablet. Since forklifts do not need to drive into the lanes, handling times are lower, storage capacity is higher and deeper. This radio shuttle solution stores more pallets deep and works with minimal clearances between levels, permitting high density storage. Handling up to 3,307 lbs. per pallet, the shuttle platform is designed to carry pallets with a 1" maximum buckling limit. Traveling at speeds of 295' per minute when empty and 148' per minute when loaded, pallet shuttles reduce loading and unloading times resulting in more productivity. The built-in sensors, enabling different types of pallets to be detected and handled, help position loads intelligently, eliminating empty spaces in the storage lanes.

The shuttle rack system is easy to use and maintain and operates in LIFO or FIFO mode. The shuttle follows orders sent by an operator through a WiFi connected tablet. It deposits its load in the first free location in the channel, while compacting the pallets as much as possible. And as a scalable system, it is easy to increase the number of shuttles in operation to match increasing productivity needs—a single tablet can control up to 18 shuttles. As items are grouped by channels, more goods are flowing in and out of the warehouse providing greater product diversification. While the pallet shuttle carries out a command, the operator collects another pallet achieving continuous workflows.

The Pallet Shuttle system offers a compact storage solution that reduces operating costs and improves supply chain performance. These benefits, combined with its efficient energy use, lead to immediate cost savings, making the Pallet Shuttle one of the most cost-effective compact storage systems around.

FEATURES

Greater diversification since each channel houses a different item

Greater diversification since each channel houses a different item- High productivity through increased inflows and outflows of goods

- Greater capacity (deep store pallets in up to 131' lanes)

- Highly cost-effective, thanks to reduced operating costs

- Decreased incidents and maintenance costs

- Multiple advanced functionalities easily controlled from a single tablet

For more information on Interlake's Pallet Shuttle and the benefits it may have for your company's operation, contact CHC or your Sales Engineer.

Conveyor Handling Company (CHC) was founded in 1975 with sales and service branches along the Mid-Atlantic region. Our material handling solutions include: