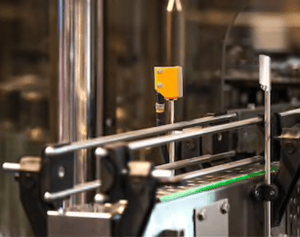

The photo eye (n)…a small piece of equipment used in the material handling industry to detect the presence of an object, such as a tote or a box, without direct contact.

The photo eye (n)…a small piece of equipment used in the material handling industry to detect the presence of an object, such as a tote or a box, without direct contact.

This small, simple tangible object hides an element of depth in its use. A photo eye, also known as a photoelectric sensor, through its light transmitting sensor captures precise data at a precise moment—data that in the material handling industry is then sent on to a conveyor controls system which is the brains of the conveyor system. Conveyor equipment varies but photoeyes can be used on all types of equipment in all different types of warehouses.

We see variations of photo eyes in our everyday use—the automatic opening of doors at a grocery store as you approach or the airport bathroom sinks that turn on with the wave of a hand under the faucet.

Like a photo that captures a moment in time—sparking a conversation, photo eye sensors, too, trigger a larger conversation. They are a starting point. By using them alongside vision scanning systems and technologies, these eyes spark a series of events encapsulating a process by which vision systems align with conveyors to track and channel movement of product throughout your warehouse.

There are three types of photo eyes to consider: through-beam, retroreflective and diffused. Each photo eye type has its own contribution to the warehouse floor. And each photo eye type detects objects at different light intensities. The through-beam photo eye, consisting of a receiver and transmitter on opposite ends but along the same line-of-sight, is the most accurate and efficient eye with the longest sensing range. A retroreflective photo eye is less accurate than a through-beam with the receiver and transmitter on one end and a reflector on the opposite end. Lastly, the diffused photo eye which hosts the receiver and transmitter on one end and nothing on the opposite end. In this last scenario, the transmission must reflect off the object in order to reach the receiver, making this option the least accurate.

Photo eyes have become more prevalent in material handling. And when used in conjunction with various innovative automated technologies, they are vital to the productivity and safety on the warehouse floor. The more precise data captured with photo eyes at various points along the conveyor, the more precise throughput. How you choose to implement photo eyes in coordination with other controls systems within your warehouse will inevitably shape your operations.

A small piece of equipment indeed, yet one that lends a big voice in keeping the conveyor lines running and helping you to see clearly, the bigger picture.

Author: Heather Connors, Director of Marketing, Conveyor Handling Company

Interested in learning more about photo eyes?