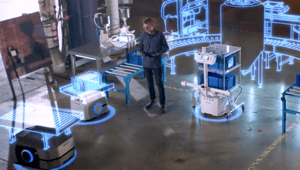

Imagine the inside of a warehouse where humans are entirely replaced with autonomous mobile robots (AMR), working in collaboration with each other for the common goal—maximizing productivity, efficiency, and profits. And all the while utilizing the best material handling resources and the most advanced technological innovative solutions in equipment to fulfill those goals. Not beyond the realms of possibility, this notion may become a more viable solution, offering more options to allocating resources in material handling.

Imagine the inside of a warehouse where humans are entirely replaced with autonomous mobile robots (AMR), working in collaboration with each other for the common goal—maximizing productivity, efficiency, and profits. And all the while utilizing the best material handling resources and the most advanced technological innovative solutions in equipment to fulfill those goals. Not beyond the realms of possibility, this notion may become a more viable solution, offering more options to allocating resources in material handling.

It’s certainly not unusual to hear talk of robotics and automation hand in hand. Robotics in the warehouse is a need that grows stronger daily as we navigate through current uncharted waters and these unprecedented times call for new, creative and innovative measures. This is when innovation takes on a new direction and dimension in the supply chain world—providing solutions to those challenges that humans alone cannot resolve.

Ask yourself these questions: What happens when employees and warehouse operators call out sick? What happens when the demand is stronger than the supply, and the physical human element in the workplace cannot sustain or maintain product delivery? Supply chain order fulfillment requires speed and a consistency to deliver—without interference.

Warehouses and fulfillment centers are in need now. Our current situation requires nurturing, feeding and fulfilling that need. Autonomous mobile robots are not necessarily new in the warehouse today, but they are drawing attention and becoming more popular to material handling automation implementation. Integrated with management and controls systems and other material handling automation, AMR’s serve as an innovative technology ideal for e-commerce and omni-channel order fulfillment operations. Unquestionably, robots and robotics in material handling do have a place in distribution and warehouse facilities in some capacity.

AMR’s fulfill processes seamlessly and can address both safety issues and footprint in the warehouse. Robots provide a detail and exactness to accomplish various tasks and processes removing human error, while optimizing the workplace. They enhance and increase accuracy and efficiency, improving and streamlining supply chains. These versatile autonomous robots provide a cover to humans if/when they are sick or out of commission from work for various reasons. Robots can eliminate obstacles and processes requiring tedious or fatiguing labor, which can result in costly investments—both equipment and labor.

AMR’s are transforming the fundamental daily processes in how every product is manufactured, produced and delivered all across the world to the consumer. A creative innovation without boundaries, this technology puts a bullseye on warehouse operations fulfilling e-commerce and omni-channel orders with precision and without pause.

As we forge our path in the material handling industry, our focus is resolute—“innovation distinguishes between a leader and a follower (Steve Jobs).” Our warehouse operations must lead with precision and accuracy. And to lead we must do so using all available tools in our toolbox.

Author: Heather Connors, Director of Marketing, Conveyor Handling Company

Interested in learning more about AMR's?